Intro

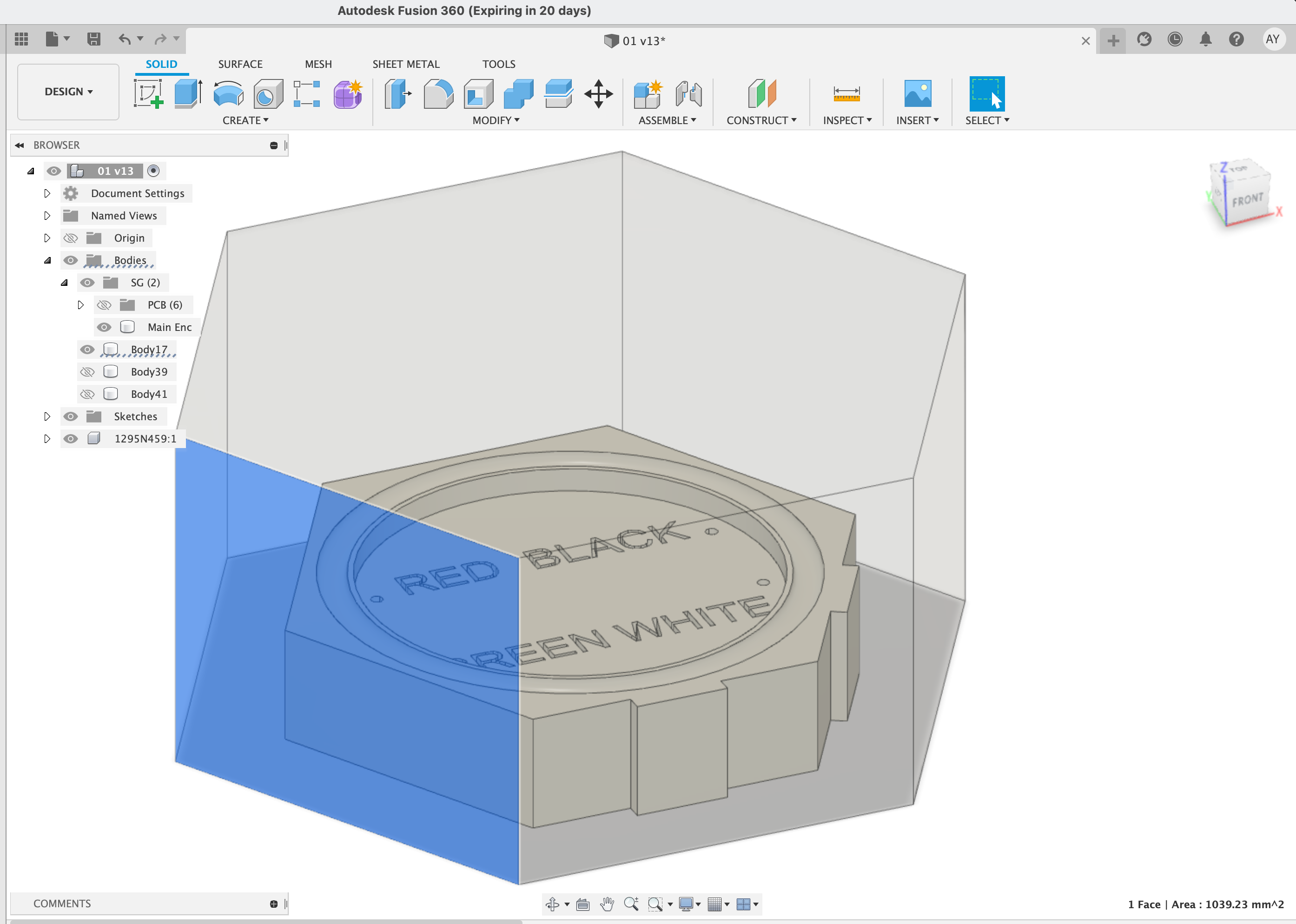

As soon as you are done assembelling your first design/PCB/device you realize that it needs a home, box or an enclosure to sit in. I have been playing with DIY boxes from stores such as Michel’s, IKEA and even repurposing some other devices’ enclosures for my projects.

The main reason has been my personal time management as I did not find a big chunk of time I could devote to build the skills needed to start CAD manufacturing, until last couple of months that I have been exposed to two major design software: Autodesk Fusion 360 and SOLIDWORK.

As a civil engineer with 15+ years of experience with AutoCAD, naturally I started with the Fusion 360 but quickly realized that SolidWorks has been around for ages and that could be why it is the first choice among engineers in many industries.

CAD Design

Structural drawing once amazed me, and this time it was CAD drawing that had me excited. The shear number of concepts and ideas involved in the journey of the design and manufacturing a functional part is intriguing to me.

But at the end you cannot name yourself a product developer if you cannot see a product from schematic all the way to a finished product with an enclosure.

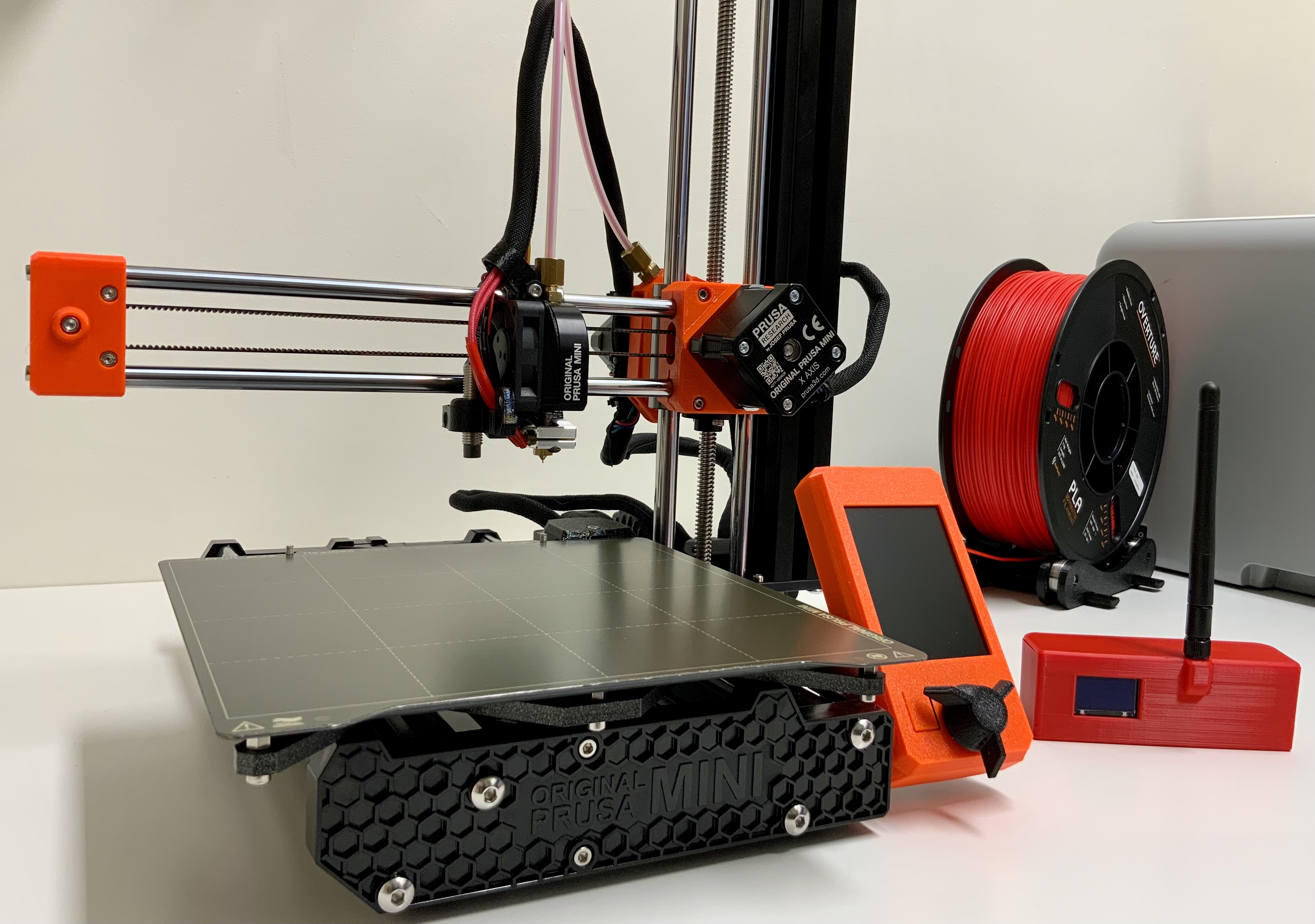

PRUSA MINI+

I am not going to talk about PRUSA as I am sure you already know everything about them. Instead let’s talk about MINI+.

I chose that because of its size, price, and good reviews. It can print all anyone as a maker is going to print. PLA, PETG and ABS.

I chose the kit because I believe DIY 3D printing involves many challenges that knowing your printer and every single piece of it can goes a long way. it took me 3 days to assemble the printer! but totally worth it!

So far, I loved the printer, it is working without giving me any problem and printing is straight forward.

I am using PLAs from AMAZON and cannot complain. I will keep this post updated.