Discussion

It certainly is not a complete product if you cannot ship it to your customer in a presentable format. One must go through the product development procedure from very first step of putting together the Schematics all the way to the finished solution inside an enclosure.

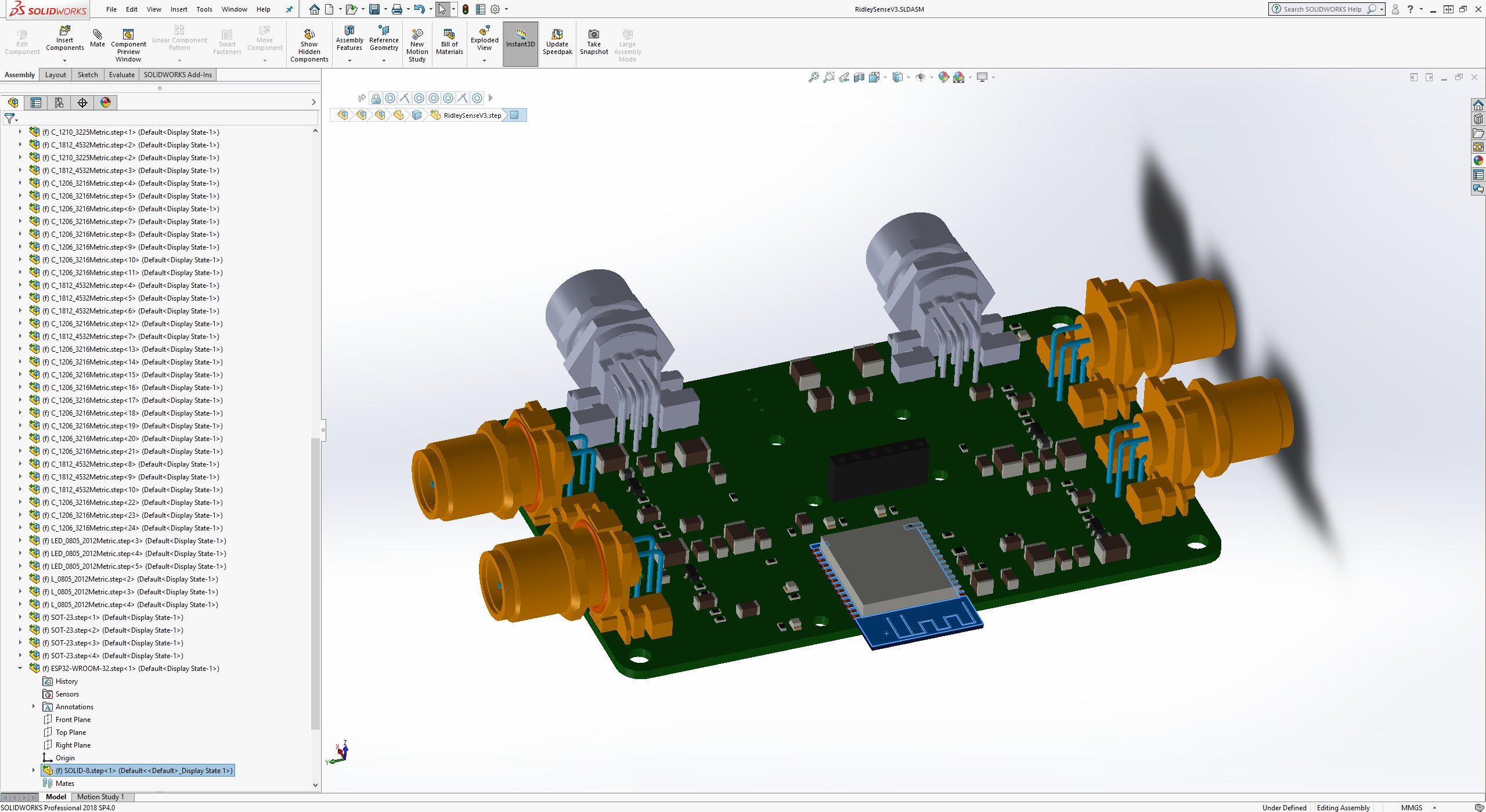

This is straight forward if it is planned ahead, and the team are aware of their workflow. SOLIDWORK is a powerful tool that enables the team to import the 3D model of the designed PCB and components.

It is critical to visually check the alignment of I/O ports and any other mountable parts the design may include before approving and finalizing the part. For many parts manufactures provide their CAD and McMaster also has a good collection of CAD design that can be directly imported to the software.

An enclosure usually has many bits and pieces that without a proper CAD design and modeling it would be very easy to make a mistake. Also, there are aspects of a product such as port accessibility and arrangement, LED and user feedback layout, and in our industry case (i.e., MINING) mounting in a harsh environment etc. that a CAD simulator software is invaluable.